Car engine parts are the intricate heart of any vehicle. Understanding their functions, interactions, and maintenance is crucial for optimal performance and longevity. This guide delves into the world of car engine components, exploring everything from basic combustion to advanced technologies.

From the fundamental components like pistons and cylinders to the sophisticated intricacies of turbochargers and variable valve timing, this resource provides a thorough overview. We’ll explore the critical roles of each part, their interplay, and how they affect overall engine efficiency and performance.

Engine Components

The internal combustion engine, the heart of most automobiles, is a complex assembly of interconnected parts working in harmony. Understanding the individual components and their relationships is crucial for appreciating the engine’s functionality and performance. Proper functioning of each component is vital for optimal engine performance, efficiency, and longevity.Engine performance is directly influenced by the interaction between various components.

For example, the efficiency of the combustion process depends on the precise timing of fuel injection and the proper functioning of the spark plugs. Similarly, the cooling system’s effectiveness determines the engine’s operating temperature, which, in turn, affects its longevity and power output.

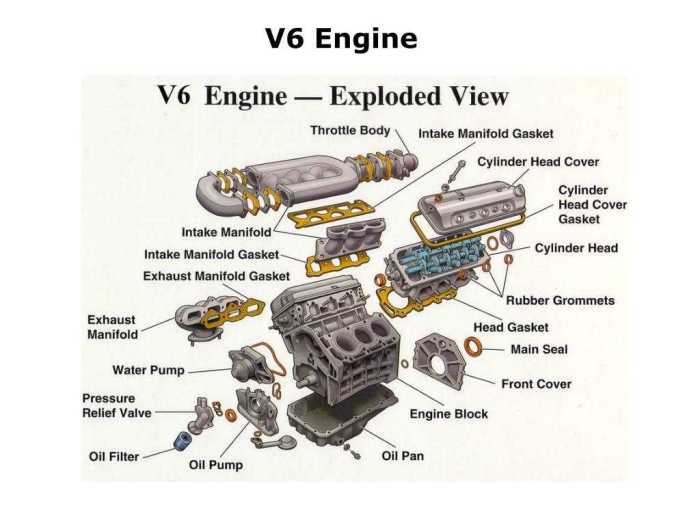

Major Engine Components

The internal combustion engine comprises numerous components, each contributing to the overall function. These components can be categorized by their primary function. The following list provides a breakdown of major engine parts and their classifications.

- Combustion Components: These parts are directly involved in the burning of fuel. This includes pistons, connecting rods, crankshaft, cylinders, valves, and spark plugs. The precise movement of pistons, driven by the expanding gases generated by the combustion process, powers the crankshaft, ultimately translating this energy into rotational motion. The arrangement and precision of these components directly influence the efficiency and power output of the engine.

- Cooling Components: Essential for maintaining optimal operating temperatures, these parts include the radiator, coolant hoses, thermostat, and water pump. A well-functioning cooling system prevents overheating, which can lead to engine damage. The thermostat regulates the flow of coolant, ensuring the engine reaches optimal operating temperature efficiently.

- Lubrication Components: These components ensure the smooth operation of moving parts by providing a protective film of oil. These include the oil pan, oil pump, oil filter, and various bearings. Proper lubrication reduces friction and wear, extending the engine’s lifespan and ensuring efficient operation.

- Power Transmission Components: These components transmit the power generated by the engine to the wheels, including the flywheel, clutch, transmission, and drive shaft. The smooth transition of power from the engine to the wheels is essential for vehicle control and performance.

- Auxiliary Components: These components support the engine’s operation, including the fuel pump, air intake system, exhaust system, and sensors. The accurate measurement of fuel and air is critical for maintaining proper combustion efficiency.

Relationship Between Engine Parts

The engine’s components are interconnected and interdependent. The performance of one component directly affects the performance of others. For instance, the pistons’ movement relies on the proper functioning of the connecting rods, which in turn depend on the crankshaft’s rotation. The smooth operation of these components is crucial for maintaining optimal engine performance.

Engine Component Materials

The selection of materials for various engine components is crucial for their durability, strength, and performance.

| Component | Common Materials | Properties |

|---|---|---|

| Pistons | Aluminum alloys | Lightweight, good heat dissipation |

| Connecting Rods | Steel alloys | High strength, good fatigue resistance |

| Crankshaft | Steel alloys | High strength, good fatigue resistance, and stiffness |

| Cylinders | Cast iron, Aluminum alloys | High strength, good heat resistance, and wear resistance |

| Valves | Steel alloys | High strength, heat resistance, and good corrosion resistance |

Manufacturing Processes

Engine components are manufactured using various techniques, each with specific advantages and limitations.

- Casting: This process involves pouring molten metal into a mold to create the desired shape. It’s often used for creating engine blocks and cylinder heads. The quality of the casting depends heavily on the mold’s design and the metal’s properties.

- Machining: This process involves removing material from a workpiece using tools to create precise shapes and dimensions. It’s crucial for producing parts with tight tolerances, such as pistons, connecting rods, and crankshaft components. The accuracy of machining directly impacts the engine’s performance.

- Forging: This process involves shaping metal under high pressure and temperature. It’s used for creating components requiring high strength and durability, such as connecting rods and crankshafts. The forging process creates a strong, uniform microstructure within the component.

Engine Performance Metrics

Engine performance is a critical aspect of vehicle operation, directly impacting fuel efficiency, power output, and overall driving experience. Understanding the metrics used to assess engine performance is essential for both design and maintenance. Different engine types exhibit varying characteristics in these metrics, reflecting their specific design and operating principles.Engine performance metrics are not merely abstract numbers; they translate into real-world advantages and disadvantages.

A higher horsepower output, for instance, allows for faster acceleration and higher top speeds, while better fuel efficiency translates to lower running costs and a reduced environmental impact. Understanding these metrics is vital for making informed decisions about engine selection and maintenance.

Performance Metrics Overview

Various metrics are used to quantify engine performance. These metrics provide a standardized way to compare different engine designs and assess their effectiveness. Key metrics include horsepower, torque, and fuel efficiency.

- Horsepower (hp) measures the power output of an engine at a specific speed. It is a measure of the rate at which work is done. A higher horsepower engine generally indicates a greater ability to accelerate and maintain speed. For example, a high-performance sports car typically boasts a high horsepower engine to achieve rapid acceleration and top speeds.

A common misconception is that higher horsepower always correlates with better fuel economy; this is not necessarily true. Engine design, operating conditions, and other factors play crucial roles.

- Torque measures the twisting force produced by the engine. It is often expressed in pound-feet (lb-ft) or Newton-meters (Nm). Torque is critical for acceleration, especially at lower speeds. For example, a heavy-duty truck needs high torque to propel its large mass. While high horsepower may be associated with brisk acceleration at higher speeds, high torque is paramount for immediate acceleration and pulling power at lower speeds.

- Fuel Efficiency (mpg or L/100km) quantifies the fuel consumption of an engine per unit of distance or time. Higher fuel efficiency translates to lower running costs and a reduced environmental footprint. Factors like engine design, driving conditions, and driver habits influence fuel efficiency.

Engine Type Comparisons

Different engine types exhibit distinct performance characteristics. The choice of engine type often depends on the specific needs and requirements of the application.

| Engine Type | Horsepower | Torque | Fuel Efficiency | Other Considerations |

|---|---|---|---|---|

| Internal Combustion Engine (ICE) | Generally varies widely depending on the specific engine design, from low-power applications to high-performance variants. | Torque output is often high at lower RPM ranges, providing good low-end power. | Efficiency varies significantly depending on the engine design, operating conditions, and driver habits. | Requires fuel and maintenance, and produces emissions. |

| Electric Motor | Typically produces a high amount of torque at low speeds. | Torque is often very high and consistent throughout the RPM range. | High efficiency, often significantly better than ICE engines under typical driving conditions. | Reliant on charging infrastructure and battery life. |

Calculating Fuel Efficiency

Fuel efficiency can be calculated using the following formula:

Fuel Efficiency = (Distance Driven in miles or kilometers) / (Fuel Consumed in gallons or liters)

This calculation assumes consistent driving conditions and fuel type.

Impact of Wear on Performance

Engine part wear, including components like pistons, valves, and bearings, directly impacts performance metrics. Wear can result in reduced horsepower, torque, and fuel efficiency. The extent of the impact depends on the severity and extent of the wear.

- Valve Leakage can cause a drop in power and efficiency.

- Damaged Piston Rings can cause reduced compression and loss of power.

- Worn Bearings result in increased friction and reduced power output.

Regular maintenance and timely component replacement are essential to mitigate the impact of wear on engine performance.

Maintenance and Repair

Proper maintenance and timely repair are crucial for maximizing the lifespan and performance of any car engine. Regular upkeep prevents minor issues from escalating into costly repairs. A well-maintained engine runs smoother, uses less fuel, and produces fewer emissions. Understanding the intricacies of engine maintenance empowers you to proactively address potential problems, avoiding unexpected breakdowns and extending the life of your vehicle.

Routine Maintenance Checklist

Regular maintenance tasks, performed at scheduled intervals, are essential to prevent major engine problems. This checklist Artikels key procedures for maintaining optimal engine function.

- Oil Changes: Regular oil changes are paramount for maintaining engine health. Fresh oil lubricates moving parts, reducing friction and wear. Following the manufacturer’s recommended oil change intervals ensures optimal engine performance and longevity.

- Filter Replacements: Air filters, fuel filters, and cabin air filters are vital for maintaining clean fuel and air intake. Clogged filters restrict airflow and fuel delivery, hindering engine performance. Regular filter replacements are essential for efficient engine operation.

- Coolant Checks and Top-ups: Coolant is essential for regulating engine temperature. Insufficient coolant can lead to overheating and damage. Checking and topping off coolant levels as needed prevents potential engine damage.

- Spark Plug Inspection and Replacement: Spark plugs ignite the air-fuel mixture in the combustion chamber. Damaged or worn spark plugs can disrupt the ignition process, resulting in poor engine performance. Regular inspection and replacement, when needed, ensure smooth combustion and optimal power delivery.

- Belt Tension and Inspection: Engine belts transmit power to various components. Loose or damaged belts can cause malfunctions or breakdowns. Regular inspection and tensioning of these belts are crucial for engine reliability.

Diagnosing Common Engine Problems

Diagnosing engine problems requires a systematic approach. Identifying the symptoms and performing thorough checks are key steps in pinpointing the root cause.

- Identifying Symptoms: Note any unusual noises, such as knocking, rattling, or grinding sounds. Pay attention to performance issues, like rough idling, hesitation, or loss of power. Assess fuel consumption and emissions. Changes in these factors can indicate underlying problems.

- Visual Inspection: Inspect the engine visually for leaks, unusual discoloration, or damage to components. Check for loose or damaged belts and hoses. Visual cues can often provide crucial initial insights.

- Using Diagnostic Tools: Utilizing diagnostic tools, like a scanner, can help pinpoint the exact problem codes. This detailed information aids in accurate diagnosis and efficient troubleshooting.

Repair Techniques for Specific Parts

Specific repair techniques are crucial for efficient and safe repairs. The following examples highlight common repair methods.

- Spark Plug Replacement:

- Gather necessary tools, including a spark plug socket set and wrench.

- Warm up the engine to release tension on the components.

- Disconnect the spark plug wire.

- Unscrew the old spark plug using the socket.

- Install the new spark plug and tighten it to the specified torque.

- Reconnect the spark plug wire.

This procedure ensures a proper spark plug replacement without damaging any parts.

Importance of Lubrication

Proper lubrication is vital for minimizing friction and wear within engine components. A well-lubricated engine runs smoother, quieter, and more efficiently.

- Effect on Engine Parts: Lubricants like engine oil reduce friction between moving parts, preventing wear and tear. This protection extends the lifespan of components, such as bearings, pistons, and connecting rods. Reduced friction translates to improved fuel economy and reduced engine noise.

Fuel System Components

The fuel system is a crucial component of any internal combustion engine. It’s responsible for delivering the correct amount of fuel to the engine at the right time, ensuring optimal combustion and power output. Proper functioning relies on a network of interconnected parts, each playing a specific role. Understanding these components and potential issues is vital for maintaining engine performance and longevity.

Fuel Pump

The fuel pump is responsible for drawing fuel from the fuel tank and pressurizing it to deliver it to the rest of the fuel system. Different types of fuel pumps exist, including electric pumps, which are commonly used in modern vehicles. Their operation is critical to providing a consistent fuel flow.

- Function: The fuel pump draws fuel from the tank, usually under vacuum or by mechanical or electrical means, and pressurizes it to a suitable pressure for the engine. This pressurized fuel is then directed to the fuel filter and other components of the system.

- Potential Problems: A failing fuel pump can result in a lack of fuel delivery to the engine, leading to engine stalling or failure to start. Other potential issues include pump noises, which could indicate a problem like cavitation or internal wear.

- Consequences of Improper Maintenance: Neglecting fuel pump maintenance can lead to premature pump failure. A failing pump might also create inconsistent fuel pressure, leading to erratic engine performance.

Fuel Filter

The fuel filter’s function is to remove impurities and contaminants from the fuel before it reaches the engine. This ensures that the engine receives clean fuel, preventing damage to crucial components like the injectors and the fuel pump.

- Function: The fuel filter acts as a barrier, trapping sediment, water, and other contaminants from the fuel. This ensures that only clean fuel is delivered to the engine, protecting it from damage.

- Potential Problems: A clogged fuel filter can restrict fuel flow, leading to reduced engine power and efficiency. Contaminants can also damage fuel injectors, leading to potential engine misfires or even complete engine failure.

- Consequences of Improper Maintenance: Skipping regular fuel filter replacements can result in the accumulation of debris in the filter. This debris can then clog the filter, leading to a lack of fuel to the engine.

Fuel Injectors

Fuel injectors are responsible for precisely metering the fuel into the engine’s combustion chambers. Modern fuel injection systems use electronically controlled injectors, enabling precise fuel delivery.

- Function: Fuel injectors atomize and spray the fuel into the intake manifold or cylinders. This is a critical process for efficient combustion. The amount of fuel delivered is regulated by electronic signals.

- Potential Problems: Clogged injectors can restrict fuel flow, resulting in poor engine performance or rough idling. Faulty injectors may not deliver the fuel at the right time, causing misfires and decreased power. Leaking injectors can lead to fuel leaks and potential engine damage.

- Consequences of Improper Maintenance: Insufficient maintenance of injectors, such as ignoring regular cleaning or inspections, can result in a buildup of deposits, affecting fuel atomization and engine performance. Improper maintenance can also lead to damage to the injector itself.

Fuel Quality

Fuel quality significantly impacts engine performance. Using low-quality fuel can lead to various issues, such as deposits in the fuel system, injector clogging, and engine damage.

- Impact on Engine Performance: Poor fuel quality can contain contaminants like water or excessive amounts of ethanol. This can cause issues ranging from poor acceleration to engine misfires and rough idling. The presence of contaminants can also accelerate the buildup of deposits in fuel injectors, potentially leading to more significant problems.

Cooling System Components

The cooling system is a vital part of any internal combustion engine, ensuring optimal operating temperatures. Proper cooling prevents overheating, which can lead to significant engine damage and reduced lifespan. A well-functioning cooling system effectively dissipates heat generated during combustion, allowing the engine to operate reliably and efficiently.

Role of Cooling System Components

The cooling system’s components work in concert to regulate engine temperature. Each component plays a specific role in the overall cooling process.

- Radiator: The radiator is the primary heat exchanger in the system. It is filled with coolant, which absorbs heat from the engine. Coolant then flows through the radiator’s fins, where heat is transferred to the surrounding air. This process lowers the coolant temperature, which is then circulated back to the engine.

- Thermostat: The thermostat regulates the flow of coolant through the engine. At low temperatures, the thermostat restricts coolant flow to the radiator, allowing the engine to quickly reach operating temperature. Once the engine reaches the optimal operating temperature, the thermostat opens, allowing coolant to circulate through the radiator to maintain the desired temperature.

- Hoses: Hoses are crucial for transporting coolant between the engine, radiator, and other components. They ensure proper coolant circulation, preventing leaks and ensuring efficient heat transfer. High-quality hoses are essential for preventing failure, which can lead to coolant loss and engine overheating.

- Water Pump: The water pump circulates the coolant throughout the cooling system. It is a vital component, ensuring that the coolant is consistently moving, effectively transferring heat from the engine to the radiator.

Comparison of Cooling System Designs

Different cooling systems are employed in various engine designs. The choice depends on factors like engine size, application, and desired performance.

- Air-cooled systems: In air-cooled systems, the engine block is directly exposed to air. A network of fins and channels facilitates heat dissipation. This system is simpler and lighter than liquid-cooled systems, but it often requires more maintenance and is less efficient at high operating temperatures, particularly in larger engines.

- Liquid-cooled systems: Liquid-cooled systems use a circulating coolant (water or antifreeze mixture) to transfer heat from the engine to a radiator. This method is more efficient in removing heat than air cooling, enabling higher operating temperatures and greater engine output. The use of antifreeze in liquid cooling systems prevents freezing and provides better heat transfer than pure water.

Significance of Efficient Cooling

Maintaining efficient cooling is critical for engine health and longevity. Overheating can cause several detrimental effects:

- Damage to Engine Components: Excessive heat can lead to warping, cracking, and distortion of engine components like pistons, cylinder heads, and gaskets. This can necessitate costly repairs or replacement.

- Reduced Engine Performance: When the engine overheats, it reduces its ability to function effectively. Reduced efficiency can result in decreased power output and increased fuel consumption.

- Potential for Engine Failure: Severe overheating can cause catastrophic engine failure. This failure can range from a loss of power to complete engine seizure, leading to costly repairs.

Causes of Cooling System Failure

Several factors can contribute to cooling system failure. Identifying the cause is crucial for prompt resolution.

| Cause | Description |

|---|---|

| Coolant Leaks | Leaks in hoses, radiator, or water pump can lead to coolant loss and overheating. |

| Blocked Radiator Fins | Accumulation of dirt, debris, or scale can restrict heat transfer, leading to overheating. |

| Faulty Thermostat | A malfunctioning thermostat may not allow coolant to circulate properly, potentially causing overheating or insufficient cooling. |

| Damaged Water Pump | A damaged water pump cannot circulate coolant effectively, resulting in insufficient cooling. |

| Low Coolant Level | Insufficient coolant reduces the cooling capacity, leading to overheating. |

Lubrication System Components

The lubrication system is critical to the smooth and efficient operation of any internal combustion engine. It ensures proper lubrication of moving parts, reducing friction and wear, and maintaining optimal engine performance. A well-maintained lubrication system extends engine lifespan and prevents costly repairs.

Components of the Lubrication System

The lubrication system comprises several interconnected components, each playing a vital role in the process of supplying and circulating oil throughout the engine. Proper understanding of each component’s function is key to maintaining the system’s effectiveness.

- Oil Pump: The oil pump is responsible for circulating engine oil throughout the lubrication system. It draws oil from the oil pan and forces it through the system under pressure. This pressure is essential for ensuring proper lubrication of all moving parts. Failure of the oil pump results in insufficient lubrication, leading to significant engine wear and potential damage.

- Oil Filter: The oil filter removes impurities, such as metal particles and debris, from the oil. This filtration process ensures that only clean oil is circulated through the engine. A clogged or malfunctioning oil filter reduces the effectiveness of the lubrication system, allowing contaminants to reach vital engine parts and accelerating wear.

- Oil Pan: The oil pan is a reservoir that holds the engine oil. It collects the used oil and acts as a reserve supply for the oil pump. The oil pan’s design also helps to maintain the correct oil level within the engine.

- Oil Pressure Sensor: The oil pressure sensor monitors the pressure of the oil circulating through the engine. This data is relayed to the engine’s control unit, allowing for adjustments to ensure optimal lubrication. Low oil pressure can indicate a problem with the oil pump, filter, or other components, requiring immediate attention.

- Oil Dipstick: The oil dipstick is a critical tool for checking the oil level and condition. By checking the oil level regularly, drivers can quickly identify potential issues and maintain the proper oil level. The color and consistency of the oil can also provide insights into the overall health of the engine.

Importance of Proper Oil Change Intervals

Regular oil changes are crucial for maintaining a healthy lubrication system. Contaminants and debris build up in the oil over time, reducing its effectiveness as a lubricant. Following recommended oil change intervals, typically specified by the vehicle manufacturer, is essential for optimal engine performance and longevity.

Understanding car engine parts is crucial, but pinpointing issues often requires engine diagnostics. Properly identifying problems with a car’s internal mechanisms, like the pistons or the crankshaft, is made easier with tools for engine diagnostics. Ultimately, a solid grasp of these parts is key for any car enthusiast.

- Engine Wear Prevention: Proper oil change intervals prevent premature engine wear and tear by keeping the oil clean and free of contaminants. This helps to maintain the engine’s overall health and prolong its lifespan.

- Fuel Efficiency: Clean oil reduces friction and improves fuel efficiency. This is because the reduced friction allows the engine to operate more efficiently, leading to better fuel economy.

- Emissions Control: Oil changes can help to maintain proper engine emissions. Contaminated oil can affect the performance of emission control systems, potentially leading to higher emissions.

Impact of Improper Lubrication on Engine Wear, Car engine parts

Improper lubrication leads to accelerated engine wear and potential damage. Without adequate lubrication, friction between moving parts increases significantly, generating heat and accelerating the deterioration of engine components. This can manifest in various ways, from reduced performance to catastrophic engine failure.

- Increased Friction: Insufficient lubrication results in excessive friction between moving parts, leading to increased wear and tear. This can lead to premature failure of bearings, pistons, and other critical components.

- Heat Generation: Increased friction generates excessive heat, which can damage engine components and lead to warping or deformation. This heat can also degrade the oil’s lubricating properties, creating a vicious cycle of increased wear and damage.

- Reduced Engine Performance: Improper lubrication can lead to reduced engine performance, including loss of power, increased fuel consumption, and difficulty starting. These issues can be costly to repair and indicate a need for immediate attention.

Ignition System Components

The ignition system is crucial for initiating the combustion process within an internal combustion engine. It converts electrical energy into the spark needed to ignite the air-fuel mixture, thus driving the engine. Proper functioning of the ignition system is essential for reliable engine performance and overall vehicle operation.The ignition system’s components work in concert to deliver a high-voltage spark to the spark plugs at precisely the right time.

This timing is critical for efficient combustion and engine performance. Malfunctions in any component can lead to misfires, reduced power, and potentially engine damage.

Spark Plugs

Spark plugs are the critical components responsible for initiating the combustion process. They create a high-voltage spark across a gap within the combustion chamber. A good spark plug ensures reliable ignition.The spark plug’s electrode gap and material are crucial for optimal performance. The gap ensures that the spark is strong enough to ignite the fuel-air mixture, while the material ensures longevity and resistance to heat.

A faulty spark plug can lead to misfires, reduced power output, and rough engine operation.

Car engine parts are crucial for optimal performance. A vital component often overlooked is the battery, and its replacement can significantly impact overall engine health. Proper battery replacement, like the one detailed here , is key for a smooth running engine. Ultimately, maintaining all these components keeps your car running efficiently.

Distributor (in older systems)

The distributor, commonly found in older vehicles, distributes the high-voltage spark from the coil to the spark plugs. It also controls the timing of the spark delivery, coordinating with the engine’s rotation. The distributor’s rotor and contacts ensure a reliable spark to the appropriate cylinder at the correct moment. Problems with the distributor, such as worn contacts or a faulty rotor, can result in misfires and uneven engine performance.

Ignition Coil

The ignition coil is an electrical component that boosts the voltage from the battery to a level high enough to create a spark across the spark plug gap. It transforms the lower voltage from the battery into the high voltage required for ignition. A faulty coil can cause misfires, poor acceleration, and potentially engine stalling.

Ignition Timing

Ignition timing is the precise moment when the spark is delivered to the spark plugs relative to the engine’s crankshaft position. Proper timing is essential for efficient combustion and optimal engine performance. Advancement or retardation of timing can significantly impact power output and fuel efficiency.Precise ignition timing is crucial for achieving optimal engine performance. Misaligned timing can lead to decreased power output, poor fuel economy, and potential engine damage.

Modern electronic ignition systems often use sophisticated sensors to ensure precise timing.

Comparison of Ignition System Designs

| Feature | Distributor-Based System | Electronic Ignition System |

|---|---|---|

| Spark Timing Control | Mechanical, based on distributor rotation | Electronic, controlled by sensors and a computer |

| Reliability | Generally less reliable due to wear and tear | Highly reliable, with reduced maintenance |

| Fuel Economy | Potentially lower fuel economy | Potentially better fuel economy |

| Complexity | Relatively simple | More complex, requiring specialized components |

| Cost | Typically less expensive initially | Often more expensive initially |

Potential Issues and Causes

Faulty ignition components can stem from various issues. Worn spark plug electrodes can result in weak sparks. A faulty ignition coil can cause inconsistent spark output. A damaged distributor (in older systems) may lead to misfiring due to improper spark timing. Problems in the ignition system often manifest as misfires, rough idling, reduced power, or engine stalling.

Proper diagnosis is crucial for effective troubleshooting and repair.

Advanced Engine Technologies

Modern engines are constantly evolving, incorporating advanced technologies to improve performance, efficiency, and reduce emissions. These advancements build upon traditional designs, introducing significant modifications and refinements that impact various aspects of engine operation. This section delves into key modern engine technologies, comparing them with their traditional counterparts, and highlighting their advantages and disadvantages.

Turbocharging

Turbocharging significantly boosts engine power by forcing more air into the combustion chamber. This increased air supply allows for a greater fuel-air mixture, leading to higher power output. Compared to naturally aspirated engines, turbocharged engines exhibit substantial gains in torque and horsepower, particularly at lower RPMs. This is often crucial for performance-oriented vehicles, as well as in diesel applications.

- Benefits: Turbocharging enhances engine performance, providing a significant power boost, especially at lower RPMs, making it suitable for various applications, including passenger cars and trucks. It also improves fuel efficiency in some cases by allowing for leaner combustion.

- Drawbacks: Turbo lag, a delay in power delivery, is a common issue. Proper turbocharger design and tuning are essential to mitigate this. Also, the added complexity of turbocharging systems can lead to higher maintenance costs. Overheating and potential damage to components can occur if not adequately managed.

Variable Valve Timing (VVT)

Variable valve timing systems dynamically adjust the opening and closing times of intake and exhaust valves. This enables the engine to optimize valve operation across various engine speeds and loads. This technology is a significant improvement over traditional fixed valve timing, allowing for better fuel efficiency and performance.

- Benefits: VVT systems enhance engine performance by adapting to different operating conditions. They improve torque delivery across a broader RPM range, leading to smoother acceleration and better fuel economy. This also leads to a reduction in emissions.

- Drawbacks: The increased complexity of VVT systems introduces additional components and potentially higher maintenance requirements. The cost of these systems can be a factor in overall vehicle pricing.

Future Trends in Engine Design

Future engine designs are expected to focus on further optimizing efficiency and reducing emissions. Hybrid and electric powertrains are likely to play a significant role, with advancements in battery technology and motor efficiency. Furthermore, the development of highly efficient internal combustion engines (ICE) that incorporate various advanced technologies, such as advanced materials, and improved combustion processes, is anticipated.

- Example: The increasing use of mild hybrid systems in many modern vehicles demonstrates the move towards hybrid powertrains. These systems provide slight improvements in fuel economy and driving experience without sacrificing the traditional driving feel.

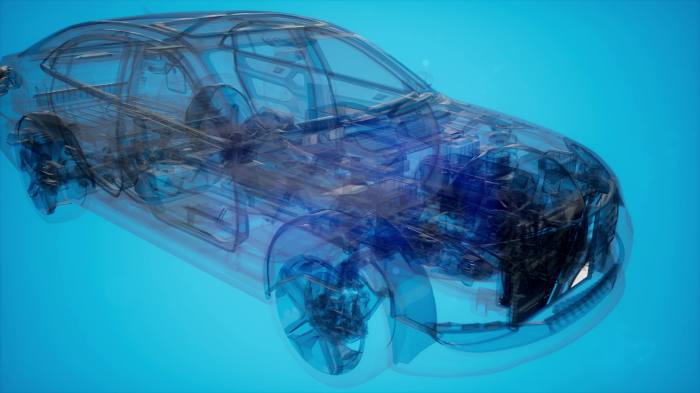

Engine Part Diagrams

A comprehensive understanding of internal combustion engines hinges on familiarity with their constituent parts and how they interact. Visual representations, such as diagrams, provide invaluable insights into the complex machinery, aiding in maintenance, troubleshooting, and design optimization. Detailed diagrams illuminate the intricate pathways of fuel, air, and energy flow, allowing for a more profound appreciation of the engine’s functionality.Visualizing engine components in their entirety, and their interplay, empowers engineers and technicians to address problems efficiently and design more effective systems.

This section presents crucial diagrams and tables to illustrate the inner workings of a typical 4-cylinder engine.

Typical 4-Cylinder Engine Components

Understanding the arrangement and function of engine parts is fundamental to grasping engine operation. The following table details the key components of a standard 4-cylinder engine.

| Component | Description |

|---|---|

| Cylinder Block | The main body of the engine, housing the cylinders. |

| Cylinder Head | Covers the top of the cylinders, containing valves, spark plugs (in gasoline engines), and coolant passages. |

| Pistons | Move up and down within the cylinders, converting pressure into mechanical work. |

| Connecting Rods | Link the pistons to the crankshaft, transmitting the reciprocating motion. |

| Crankshaft | Converts the reciprocating motion of the pistons into rotational motion. |

| Valves (Intake/Exhaust) | Control the flow of air and exhaust gases into and out of the cylinders. |

| Camshaft | Operates the valves, timed to open and close at specific points in the engine cycle. |

| Spark Plugs (Gasoline Engines) | Initiate combustion by creating a spark within the cylinders. |

| Piston Rings | Seal the gap between the piston and cylinder wall, preventing leakage of combustion gases and oil. |

Fuel and Air Flow Diagram

The precise sequence of fuel and air intake and combustion is crucial to engine performance. The following diagram illustrates the path of fuel and air through a typical 4-cylinder engine.

(Imagine a simple diagram here showing air intake through the air filter, fuel injection into the intake manifold, mixture entering the cylinders, combustion, and exhaust gases exiting. Label key components like intake manifold, throttle body, fuel injectors, spark plugs, exhaust manifold.)

The diagram visually represents the crucial flow of fuel and air, highlighting the intricate interactions between various components.

Component Interaction Illustration

The engine’s components work in concert, with each part playing a vital role in the overall functioning. The following image depicts the interaction between the piston, connecting rod, crankshaft, and cylinder.

(Imagine a labeled diagram here showcasing the piston moving up and down, the connecting rod transmitting this motion to the crankshaft, and the crankshaft converting this into rotational motion. Label the piston, connecting rod, crankshaft, cylinder, and show the direction of motion.)

The image effectively demonstrates how the reciprocating motion of the piston is transformed into the rotational output of the crankshaft. This crucial interaction is essential for power generation in the engine.

Engine Block Types and Applications

Different engine block designs cater to diverse applications. The following table categorizes engine block types and their suitability for various tasks.

| Engine Block Type | Material | Typical Applications |

|---|---|---|

| Cast Iron | Cast Iron | Trucks, heavy-duty machinery, applications demanding high strength and durability. |

| Aluminum Alloy | Aluminum Alloy | Cars, motorcycles, and applications requiring lighter weight and better heat dissipation. |

| Magnesium Alloy | Magnesium Alloy | High-performance applications needing exceptional lightness, often in racing. |

Final Thoughts: Car Engine Parts

In conclusion, understanding car engine parts is essential for any vehicle owner. This guide has provided a detailed look at various components, their functions, maintenance, and the impact on performance. Whether you’re a seasoned mechanic or a curious enthusiast, this information equips you with a strong foundation for maintaining your vehicle’s health and maximizing its potential.

FAQ

What are the common causes of engine misfires?

Engine misfires can stem from several issues, including faulty spark plugs, ignition timing problems, fuel delivery issues, or even a problem with the engine’s sensors.

How often should I change my engine oil?

Oil change intervals vary depending on the vehicle’s make, model, and driving conditions. Consult your owner’s manual for specific recommendations.

What are the signs of a failing radiator?

Signs of a failing radiator include overheating, leaks, reduced coolant levels, or unusual noises.

What is the difference between a four-cylinder and a six-cylinder engine?

Generally, six-cylinder engines tend to provide more power and smoother operation compared to four-cylinder engines, though fuel efficiency can vary. The number of cylinders directly impacts the engine’s capacity and therefore its power output.