Auto Repair & Maintenance is crucial for vehicle longevity and safety. This guide covers everything from basic maintenance to advanced repair techniques, DIY tips, and professional services. We’ll explore common problems, maintenance schedules, and the environmental impact of repairs.

Understanding your vehicle’s needs is key to avoiding costly repairs. This guide will walk you through the intricacies of auto repair, from identifying issues to performing simple maintenance tasks yourself or finding a qualified professional. We’ll also discuss the importance of safety precautions and eco-friendly practices.

Introduction to Auto Repair & Maintenance

Auto repair and maintenance is a crucial field that ensures the safe and efficient operation of vehicles. It encompasses a wide range of tasks, from routine checks to complex repairs, playing a vital role in public safety and economic productivity. The field’s importance stems from its ability to keep vehicles running smoothly, prolonging their lifespan, and preventing costly breakdowns.

Types of Auto Repair and Maintenance Tasks

Various tasks fall under the umbrella of auto repair and maintenance. These include routine services like oil changes, tire rotations, and fluid checks, as well as more complex repairs like engine overhauls, transmission replacements, and electrical system diagnostics. The scope of tasks varies significantly based on the type of vehicle and the specific issues encountered.

Specializations within the Field

Auto repair and maintenance encompasses several specialized areas. Engine repair, focusing on the internal combustion engine, is a core specialization. Transmission repair involves diagnosing and rectifying problems within the vehicle’s transmission system. Electrical system repair focuses on the complex network of wires, components, and sensors that power and control the vehicle’s functions. Other specializations include brake repair, suspension repair, and body work.

Each specialization requires specific knowledge and skills, often involving specialized tools and techniques.

Tools and Equipment Commonly Used

The auto repair and maintenance industry utilizes a wide array of tools and equipment. Common tools include wrenches, sockets, screwdrivers, pliers, and various gauges. Specialized equipment such as diagnostic scanners, engine analyzers, and alignment tools is also essential. The selection of tools and equipment depends on the specific tasks being performed and the complexity of the repair.

Vehicle Maintenance Schedules

Maintaining a vehicle’s optimal condition involves adhering to specific maintenance schedules. These schedules vary based on the vehicle type and manufacturer recommendations. Adherence to these schedules can significantly extend the lifespan of the vehicle and prevent costly repairs.

| Vehicle Type | Maintenance Schedule (Miles/Months) |

|---|---|

| Sedan | Oil change every 3,000-5,000 miles or 3-6 months; Tire rotation every 5,000-7,500 miles; Fluid checks every 3-6 months. |

| SUV | Oil change every 3,500-7,000 miles or 4-8 months; Tire rotation every 5,000-10,000 miles; Fluid checks every 4-8 months. |

Common Auto Repair Problems: Auto Repair & Maintenance

A multitude of issues can plague vehicles, ranging from minor annoyances to major breakdowns. Understanding these common problems and their causes is crucial for proactive maintenance and informed decision-making regarding repairs. Addressing these issues promptly can save significant costs and prevent more serious complications down the line.Identifying and addressing these issues often involves a combination of meticulous inspection, diagnostic testing, and a good understanding of vehicle mechanics.

By learning about the common pitfalls and their potential solutions, vehicle owners can be more prepared to navigate the world of automotive repair.

Frequent Issues in Vehicle Repair

Several recurring problems consistently appear in vehicle repair shops. These issues often stem from factors like wear and tear, neglectful maintenance, or, unfortunately, accidents. Recognizing these patterns helps prioritize preventive measures and make informed decisions about repairs.

Causes of Common Problems

Various factors contribute to the frequency of specific auto repair issues. Wear and tear, a natural consequence of use, gradually degrades components, leading to malfunctions. Neglecting scheduled maintenance, like oil changes or tire rotations, can accelerate the deterioration of parts and systems, causing unforeseen issues. Accidents, whether minor fender benders or major collisions, can cause significant damage to the vehicle’s structure and internal components.

Driving habits, like aggressive acceleration or hard braking, can also exacerbate wear and tear on certain parts.

Common Car Problems and Solutions

| Problem | Possible Solution | Estimated Cost (USD) |

|---|---|---|

| Battery Issues (e.g., low charge, failure) | Battery replacement, jump start, charging system inspection | $50-$300 |

| Engine Problems (e.g., misfiring, overheating) | Spark plug replacement, coolant system check, sensor replacement, engine repair | $100-$1000+ |

| Transmission Issues (e.g., slipping, grinding) | Transmission fluid change, transmission repair, or replacement | $200-$5000+ |

| Electrical Problems (e.g., faulty wiring, malfunctioning lights) | Wiring repair, fuse replacement, diagnostic testing, part replacement | $50-$500 |

| Braking System Problems (e.g., squeaking, poor stopping power) | Brake pad replacement, brake caliper repair, brake line repair, master cylinder replacement | $100-$800 |

| Suspension Issues (e.g., squeaking, knocking) | Shock absorber replacement, strut replacement, ball joint replacement, tie rod replacement | $100-$500 |

| Exhaust System Issues (e.g., leaks, rattling) | Exhaust pipe repair, catalytic converter replacement | $50-$500 |

DIY vs. Professional Repair Costs

The cost of repairs can vary significantly depending on whether a vehicle owner undertakes the repair themselves or utilizes professional services. DIY repairs, while potentially saving money, can be time-consuming and require specialized tools and knowledge. Professional mechanics possess the expertise and equipment necessary to handle complex issues efficiently, but this comes at a higher cost. For example, replacing a timing belt is a complex procedure best left to professionals due to the potentially catastrophic consequences of an error.

In some cases, DIY repairs can lead to further damage if not done correctly, increasing the overall repair cost.

DIY Auto Repair

Taking on some auto maintenance yourself can save money and build valuable skills. However, always prioritize safety and proceed with caution, especially with more complex repairs. Understanding your vehicle’s limitations and seeking professional help when necessary is crucial.A key aspect of DIY auto repair is recognizing the scope of your capabilities. While simple tasks like changing a tire or oil can be handled by a novice, more intricate repairs, such as engine work or transmission replacements, are best left to trained professionals.

Proper tools and knowledge are essential for safe and successful DIY projects.

Basic Maintenance Tasks

Understanding basic maintenance tasks is a good starting point for any DIY enthusiast. These tasks often involve simple procedures and require minimal specialized tools. Regular maintenance can prevent major problems down the line.

- Changing Oil and Filter: This is one of the most common and straightforward DIY tasks. Following the owner’s manual for specific procedures and using the correct oil type is essential for engine health. Properly disposing of used oil is crucial for environmental protection.

- Checking Tire Pressure and Condition: Regularly checking tire pressure and tread depth can prevent accidents and extend tire life. Using a tire pressure gauge and inspecting the tread pattern are essential steps. Underinflated tires can affect fuel economy and handling.

- Replacing a Fuse: Knowing how to replace a blown fuse can save you a trip to a mechanic. Locate the fuse box, identify the blown fuse, and replace it with one of the correct amperage rating. Faulty fuses can indicate underlying electrical problems.

Essential Tools for DIY Repairs

Having the right tools makes DIY repairs easier and safer. A well-equipped toolbox can cover a range of simple maintenance tasks.

| Tool | Image Description |

|---|---|

| Torque Wrench | A torque wrench is a tool used to apply a precise amount of torque to a fastener, such as a bolt or nut. It has a dial or digital display that shows the amount of torque applied. This tool is crucial for ensuring proper fastener tightness to prevent damage or malfunction. |

| Screwdrivers (Phillips and Flathead) | These are essential for disassembling and assembling various components. Different sizes and types are necessary for specific applications. Using the correct screwdriver for the job prevents stripping screws or damaging parts. |

| Socket Set | A set of sockets of different sizes and types used for tightening and loosening bolts and nuts. These tools are particularly helpful for working under the vehicle or in tight spaces. Using the correct socket size is essential for preventing damage to the fastener or the socket itself. |

| Wrench Set (open-end and adjustable) | A set of wrenches for tightening and loosening nuts and bolts. Open-end wrenches provide direct access, while adjustable wrenches are versatile for various sizes. Using the correct wrench size prevents damage to the fastener or the wrench. |

| Pliers (needle-nose, slip-joint) | Pliers are used for gripping and holding small parts, wires, and other components. Needle-nose pliers offer precise control, while slip-joint pliers are versatile for a wider range of tasks. Pliers can be used for removing or installing various components, including clips and small parts. |

Safety Tips for DIY Repairs

Prioritizing safety is paramount in any DIY auto repair project. Following safety precautions can prevent accidents and injuries.

- Use Proper Safety Gear: Always wear safety glasses, gloves, and closed-toe shoes when working under the hood or around the vehicle. Safety glasses protect your eyes from flying debris, while gloves protect your hands from cuts and chemicals. Closed-toe shoes provide protection from sharp objects.

- Work in a Well-Lit Area: A well-lit workspace ensures clear visibility of components and reduces the risk of accidents. Use work lights if needed. Good lighting is crucial for proper diagnosis and repair.

- Disconnect the Battery: Before working on any electrical components, always disconnect the vehicle’s battery to prevent electrical shocks. This step is crucial for safety.

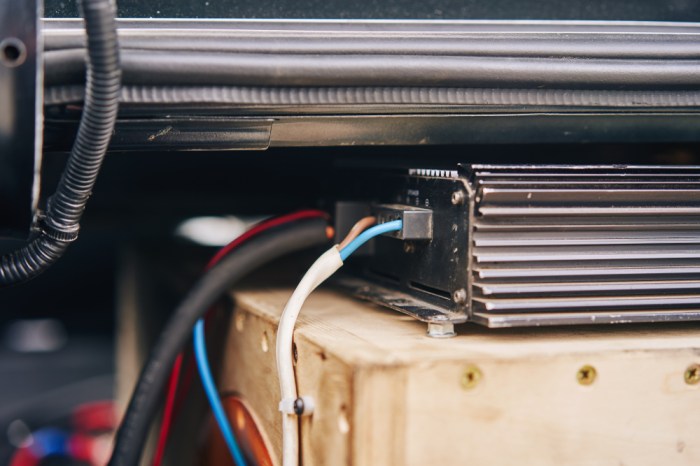

Professional Auto Repair Services

Professional auto repair services encompass a wide range of services, from routine maintenance to complex engine repairs. Finding a qualified mechanic is crucial for ensuring the safety and longevity of your vehicle. Choosing the right shop and understanding the services offered is essential for making informed decisions about your car’s upkeep.

Services Offered by Professional Mechanics

Professional mechanics offer a diverse range of services, including but not limited to, engine diagnostics, brake repairs, transmission servicing, and electrical system troubleshooting. Their expertise extends to various aspects of vehicle maintenance, from simple oil changes to intricate repairs requiring specialized tools and knowledge. Many mechanics also provide preventative maintenance recommendations, helping you avoid more significant issues down the road.

Importance of Finding a Qualified Mechanic

A qualified mechanic possesses the necessary skills, experience, and knowledge to diagnose and repair vehicle issues accurately. This expertise is critical for ensuring proper functioning and preventing potential safety hazards. Choosing an unqualified mechanic can lead to incorrect diagnoses, improper repairs, and further damage to your vehicle. Thorough research and recommendations from trusted sources are vital in finding a reputable mechanic.

Types of Repair Shops

Various types of repair shops cater to different needs and budgets. Independent garages often offer personalized service and competitive pricing. Chain auto repair shops may have standardized procedures and potentially lower labor costs. Specialized shops, such as those specializing in a particular make or model of vehicle, offer in-depth expertise. Dealership service departments provide manufacturer-backed warranties and specialized knowledge of their specific models.

Repair Shop Services and Costs

| Service | Cost Estimate | Shop Type |

|---|---|---|

| Oil Change | $50-$100 | Independent, Chain |

| Tire Rotation | $25-$50 | Independent, Chain |

| Brake Pad Replacement | $150-$300 | Independent, Chain |

| Engine Diagnostic | $75-$150 | Independent, Chain, Dealership |

| Transmission Fluid Change | $150-$300 | Independent, Chain, Dealership |

| Air Conditioning Repair | $100-$500 | Independent, Chain |

Note: Costs are estimates and can vary significantly based on the specific vehicle, parts needed, and labor rates. These estimates are for general reference.

Benefits of Choosing a Trusted Professional Repair Shop

Choosing a trusted professional repair shop offers several benefits. A reputable shop employs qualified technicians, uses quality parts, and provides detailed repair reports. They are accountable for their work, providing a warranty or guarantee on repairs. This reliability minimizes the risk of further issues arising from improper repairs. A trustworthy shop also fosters a sense of confidence in the care of your vehicle.

Auto Maintenance Schedules

Regular vehicle maintenance is crucial for optimal performance, longevity, and safety. Proper care extends the life of your car’s components, preventing costly repairs down the line. Ignoring recommended maintenance can lead to more significant and expensive problems in the future.Following a well-defined maintenance schedule is a proactive approach to vehicle upkeep. This involves understanding the manufacturer’s recommendations and adhering to them meticulously.

By consistently performing the necessary tasks, you can safeguard your vehicle from potential damage and keep it running smoothly for years to come.

Significance of Regular Maintenance

Regular maintenance is more than just keeping your car clean. It’s a proactive measure that helps identify and address minor issues before they escalate into major problems. This proactive approach saves you money in the long run by avoiding costly repairs and potential safety hazards.

Importance of Following Manufacturer’s Recommended Schedule

Adhering to the manufacturer’s recommended maintenance schedule is paramount. This schedule is meticulously developed by automotive engineers, taking into account the specific design and operating conditions of your vehicle. Deviating from these guidelines can compromise the integrity of various components, leading to premature wear and tear. Each manufacturer’s schedule is tailored to the unique features and requirements of its specific vehicle models.

Common Maintenance Tasks and Frequency

A structured maintenance schedule ensures that your vehicle receives the care it needs at the appropriate intervals. This systematic approach allows you to address issues early and prevent costly repairs. The following table Artikels common maintenance tasks and their recommended frequencies:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 3,000 to 7,500 miles (or as recommended by manufacturer) | Replaces engine oil and filter. Essential for lubrication and preventing engine wear. |

| Tire Rotation | Every 5,000 to 7,500 miles (or as recommended by manufacturer) | Rotating tires ensures even wear and tear, improving tire life and handling. |

| Fluid Checks (Brake, Power Steering, Coolant) | Every 3,000 to 6,000 miles (or as recommended by manufacturer) | Inspecting and topping off fluids ensures proper system function and prevents leaks. |

| Brake Inspection | Every 5,000 to 10,000 miles (or as recommended by manufacturer) | Checking brake pads, rotors, and brake lines for wear and tear to ensure safe braking. |

| Filter Replacement (Air, Cabin) | Every 15,000 to 30,000 miles (or as recommended by manufacturer) | Replacing air and cabin filters improves engine performance and maintains interior air quality. |

| Spark Plug Replacement | Every 30,000 to 100,000 miles (or as recommended by manufacturer) | Replacing spark plugs, when needed, optimizes engine ignition and combustion. |

| Battery Inspection | Annually or as needed | Inspecting the battery for proper voltage and condition, ensuring reliable starting. |

| Alignment Check | Every 10,000 to 20,000 miles (or as recommended by manufacturer) | Ensuring proper wheel alignment for optimal handling and tire wear. |

Consequences of Neglecting Regular Maintenance

Neglecting regular maintenance can lead to a cascade of problems. A simple oil leak can escalate into engine damage, and a worn-out tire can result in a flat or catastrophic failure. Ignoring a faulty sensor can lead to significant mechanical issues. The consequences of delayed or omitted maintenance can range from inconvenient repairs to catastrophic failures, leading to costly and time-consuming repairs.

A well-maintained vehicle not only runs better but also drives more safely.

Understanding Car Parts

A thorough understanding of car parts is crucial for effective maintenance and repair. Knowing the function, location, and construction materials of various components allows you to better identify potential problems and address them proactively. This knowledge empowers you to make informed decisions about your vehicle’s care and upkeep.

Auto Repair & Maintenance is crucial for keeping your vehicle running smoothly. Proper upkeep involves a lot more than just changing oil; it encompasses a range of services, including auto repair and diagnostics. Ultimately, these tasks ensure your car’s longevity and performance.

Key Engine Components

The engine is the heart of any vehicle, and its various components work together in a precise manner to produce power. Understanding these components is essential for troubleshooting and preventative maintenance.

| Part | Function | Location |

|---|---|---|

| Cylinder Block | Forms the structural base of the engine, housing the cylinders. | Central, usually in the lower part of the engine. |

| Pistons | Convert the pressure from the combustion process into mechanical motion, moving up and down within the cylinders. | Inside the cylinders, connected to the crankshaft. |

| Crankshaft | Transforms the reciprocating motion of the pistons into rotational motion to power the wheels. | Lower part of the engine, connected to the pistons. |

| Camshaft | Controls the opening and closing of the valves, coordinating the timing of the intake and exhaust processes. | Above the crankshaft, often within the cylinder head. |

| Valves | Regulate the flow of air-fuel mixture into the cylinders and exhaust gases out of the cylinders. | Attached to the cylinder head, controlling the intake and exhaust ports. |

| Connecting Rods | Transmit the force generated by the pistons to the crankshaft, converting linear motion to rotational motion. | Connect pistons to the crankshaft. |

| Piston Rings | Seal the gap between the piston and the cylinder wall, preventing leakage of combustion gases. | Fit within the grooves of the pistons. |

| Valvetrain | The assembly of valves, valve springs, and other components that regulate the flow of air and exhaust gases. | Located in the cylinder head, above the combustion chamber. |

| Crankshaft Seals | Prevent oil leaks from the crankshaft area and maintain the oil pressure in the engine. | Surrounding the crankshaft bearings. |

| Oil Pump | Circulates engine oil to lubricate critical components and maintain proper temperature. | Mounted on the engine block or near the crankshaft. |

| Water Pump | Circulates coolant to regulate engine temperature and maintain operating efficiency. | Mounted on the engine block, usually near the timing belt/chain. |

Materials Used in Car Part Construction, Auto Repair & Maintenance

The materials used in car part construction significantly influence the performance, durability, and cost of the component. Factors such as strength, weight, and resistance to corrosion are crucial considerations.

- Cast Iron: Frequently used in cylinder blocks for its strength and durability. Its high melting point makes it resistant to extreme temperatures, crucial for withstanding the pressure and heat generated during combustion. Examples include older engine blocks and some transmission components.

- Aluminum: Lightweight and highly corrosion-resistant, making it a popular choice for engine blocks, cylinder heads, and other components in modern vehicles. Its excellent thermal conductivity helps manage heat efficiently. Examples include many modern engine blocks, cylinder heads, and some transmission components.

- Steel: A versatile material used in various engine components due to its strength and weldability. Different grades of steel are employed depending on the specific application, ensuring the component can withstand the stresses and loads it experiences. Examples include connecting rods, crankshafts, and various structural parts.

- Plastics: Used in various engine components for its lightweight properties and resistance to corrosion. Certain plastics are engineered to withstand the high temperatures and pressures within the engine. Examples include various parts of the intake system, and some exterior components.

Role of Each Component

Each component plays a vital role in the overall functioning of the vehicle. The piston converts the pressure generated by the combustion process into mechanical motion. The crankshaft transforms this linear motion into rotational motion, which powers the wheels. The camshaft coordinates the timing of the intake and exhaust processes. The valves regulate the flow of air-fuel mixture and exhaust gases.

All these components work in tandem, ensuring efficient combustion, power generation, and smooth operation of the vehicle.

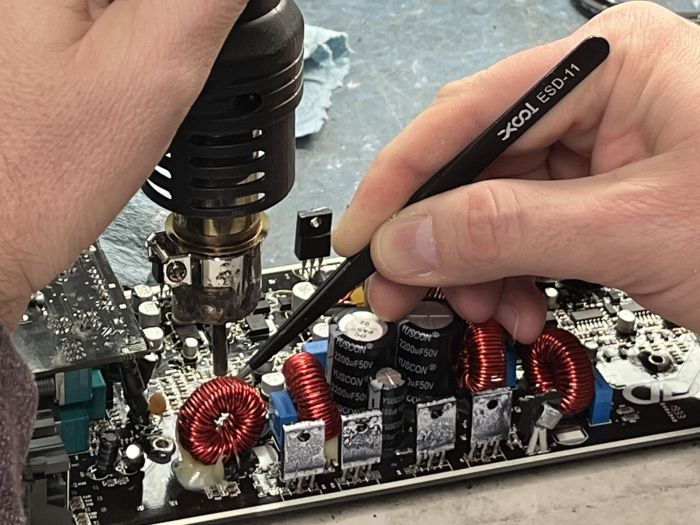

Advanced Auto Repair Techniques

Advanced auto repair techniques involve tackling complex issues requiring specialized knowledge, tools, and procedures. These techniques are often employed when standard diagnostics and repairs fail to address the problem. Mastering these advanced methods requires a deep understanding of automotive systems and a commitment to continuous learning.Complex auto repairs often necessitate a multi-faceted approach, combining in-depth diagnostics, precise component replacement, and sometimes intricate adjustments to restore optimal vehicle performance.

Auto repair and maintenance often hinges on accurate diagnoses. Understanding the inner workings of your vehicle, like using vehicle diagnostics tools and techniques, is crucial for effective repairs. This ensures you’re not just fixing symptoms, but addressing the root cause, ultimately leading to more reliable and cost-effective maintenance.

Understanding the underlying causes and mechanisms of malfunctions is crucial for successful execution of advanced repairs.

Advanced Diagnostic Techniques for Complex Issues

Advanced diagnostics for complex issues often involve sophisticated equipment beyond the scope of basic tools. This includes utilizing advanced diagnostic software, oscilloscopes, and specialized sensors to pinpoint the exact source of the problem. Detailed analysis of sensor data and system parameters is crucial to isolate faults.For example, diagnosing electrical system malfunctions may require analyzing voltage fluctuations, current flow patterns, and signal integrity with an oscilloscope.

Similarly, identifying problems within the engine management system often involves using specialized diagnostic software to analyze sensor readings and engine performance data.

Advanced Tools Used for Complex Repairs

Specialized tools play a critical role in advanced auto repair. These tools are designed for precision, accuracy, and accessibility in areas that basic tools cannot reach. Their use is essential for ensuring proper assembly and alignment, minimizing potential damage, and maximizing efficiency.Examples of specialized tools include precision torque wrenches for engine components, specialized valve spring compressors for head gasket repairs, and advanced diagnostic equipment for complex electrical systems.

Furthermore, specialized alignment tools are necessary for precise wheel alignment, ensuring proper tire contact and performance.

Comparison of Different Repair Techniques

Different repair techniques cater to varying complexities of malfunctions and component damage. Evaluating the pros and cons of each method is critical for choosing the most effective approach. Factors such as the nature of the damage, the availability of resources, and the desired outcome should be considered when selecting a repair technique.For instance, a cracked cylinder head may be repaired through welding or replacement, depending on the extent of damage and repair costs.

Engine rebuilds, for example, require a combination of component replacement, engine teardown, and reassembly, which is a more complex process compared to simple component replacements. The choice depends on the specific situation.

Environmental Impact of Auto Repair

Auto repair, while essential for maintaining vehicles, presents environmental challenges. Improper disposal of materials, use of harmful chemicals, and inefficient practices contribute to pollution and resource depletion. Understanding these impacts is crucial for adopting sustainable repair methods.The environmental footprint of auto repair extends beyond the vehicle itself. The processes involved, from sourcing parts to disposing of waste, have a significant impact on air, water, and land.

Minimizing this footprint requires a conscious effort to adopt environmentally friendly practices throughout the repair cycle.

Environmental Concerns Related to Auto Repair

The auto repair industry faces several environmental concerns. These include the use of volatile organic compounds (VOCs) in cleaning solvents, the release of harmful fumes during welding and other processes, and the generation of significant amounts of waste, including hazardous materials. Proper ventilation and emission control systems are necessary to mitigate these risks.

Importance of Eco-Friendly Products

Using eco-friendly products is crucial for reducing the environmental impact of auto repair. These products often feature reduced VOCs, are biodegradable, and are derived from renewable resources. Examples include water-based paints, biodegradable degreasers, and recycled materials in parts. This approach minimizes the release of harmful chemicals into the environment and promotes a cleaner work environment.

Impact of Waste Disposal on the Environment

Waste disposal in auto repair is a significant environmental concern. Improper disposal of used oil, batteries, fluids, and other hazardous materials can contaminate soil and water sources. This can have severe consequences for ecosystems and human health. Recycling and responsible disposal methods are essential to mitigate these risks. Specialized facilities and proper handling procedures are crucial.

Sustainable Practices for Auto Repair

Adopting sustainable practices is essential for minimizing the environmental impact of auto repair. These practices encompass various aspects of the repair process, including sourcing materials, minimizing waste, and using energy-efficient equipment.

- Waste Reduction and Recycling: Implementing comprehensive recycling programs for used parts, fluids, and materials can significantly reduce waste. Recycling programs should be in place for batteries, oil, and other hazardous materials. Proper labeling and segregation of materials at the repair shop are key to efficient recycling.

- Energy Efficiency: Utilizing energy-efficient equipment, such as low-energy lighting and electric tools, can reduce the carbon footprint of auto repair operations. Minimizing idling time for tools and equipment can further reduce energy consumption.

- Water Conservation: Implementing water-saving techniques, such as using water-efficient cleaning methods and recycling wastewater, can significantly reduce water consumption in auto repair facilities. This practice helps conserve water resources and reduces the strain on local water supplies.

- Sustainable Sourcing of Parts: Sourcing parts from suppliers committed to sustainable practices and using recycled or reclaimed materials can significantly lessen the environmental impact. This promotes the use of materials with a lower environmental footprint throughout the supply chain.

Future Trends in Auto Repair

The automotive repair industry is undergoing a period of rapid transformation, driven by technological advancements and shifting consumer demands. Understanding these emerging trends is crucial for technicians, business owners, and anyone involved in the sector to adapt and thrive in the evolving landscape. This section explores the key future trends shaping the auto repair industry.

Emerging Technologies

The auto repair industry is increasingly integrating cutting-edge technologies. This includes the use of advanced diagnostic tools, such as sophisticated scanners capable of pinpointing complex electrical faults with remarkable precision. Furthermore, 3D printing is rapidly becoming a valuable asset in the production of customized parts, especially in niche applications. This technology offers the potential for faster turnaround times and reduced material waste.

Sophisticated data analytics is also being employed to identify patterns and predict potential maintenance needs, enabling proactive measures to prevent costly breakdowns.

Impact of Electric Vehicles

The rise of electric vehicles (EVs) presents both challenges and opportunities for the auto repair industry. EVs feature different powertrain components and battery systems than traditional internal combustion engine (ICE) vehicles, demanding a shift in technician training and expertise. Specialized tools and techniques are necessary for the diagnostics and maintenance of EV battery packs and charging systems. This transition requires significant investment in training programs to equip technicians with the skills needed to work on EV systems effectively.

Repairing EV battery packs often requires more specialized equipment and expertise compared to traditional ICE vehicle maintenance.

Role of Automation

Automation is transforming various aspects of auto repair, leading to increased efficiency and reduced human error. Robotic systems are being employed in tasks like component assembly, paint application, and even some diagnostic procedures. This automation not only enhances the speed and accuracy of repairs but also allows technicians to focus on more complex or specialized aspects of the work.

Automation is also crucial for streamlining workflows and optimizing repair processes.

Future Trends Table

| Trend | Description | Impact |

|---|---|---|

| Advanced Diagnostics | Integration of sophisticated diagnostic tools for accurate fault identification. | Enhanced accuracy and efficiency in identifying and resolving issues, leading to reduced repair time and cost. |

| 3D Printing | Use of 3D printing for customized parts production. | Faster turnaround times, reduced material waste, and the ability to create bespoke parts, particularly for specialized vehicles or those with unique requirements. |

| Data Analytics | Application of data analysis to predict maintenance needs and optimize repair processes. | Proactive maintenance strategies, improved resource allocation, and reduced unexpected downtime. |

| EV Specialization | Demand for technicians with specialized knowledge and skills to work on EV systems. | Requires investment in training and development for technicians to handle the unique components and systems of EVs, leading to a shift in the skillset required in the automotive industry. |

| Automation | Implementation of robotic systems for various repair tasks. | Increased speed and accuracy in repairs, reduced human error, and optimized workflows, leading to higher efficiency in repair shops. |

Safety Precautions in Auto Repair

Auto repair, while rewarding, can be hazardous if safety measures are overlooked. Proper precautions are crucial for preventing accidents and injuries, protecting both the technician and the vehicle. Adhering to safety guidelines is paramount for a successful and injury-free repair process.Safe practices in auto repair extend beyond common sense. A systematic approach to safety, encompassing personal protective equipment, tool handling, and workspace organization, is vital.

This proactive approach minimizes risks associated with various repair tasks.

Personal Protective Equipment (PPE)

Ensuring adequate personal protective equipment (PPE) is critical for worker safety. PPE safeguards against potential hazards during repair work. Protective gear helps mitigate the risk of exposure to various elements, including harmful chemicals, flying debris, and potential physical injuries.

- Eye Protection: Safety glasses or goggles are essential to shield the eyes from flying particles, debris, and potential splashes. Goggles are recommended for tasks involving potential chemical exposure or high-speed operations.

- Hearing Protection: Exposure to loud noises from power tools and equipment can lead to hearing damage. Earmuffs or earplugs should be worn to protect hearing in noisy environments.

- Respiratory Protection: Certain repair tasks involve exposure to fumes, dust, or other airborne particles. Respirators are necessary to filter these contaminants and prevent respiratory issues.

- Hand Protection: Gloves are crucial for protecting hands from cuts, abrasions, and exposure to chemicals. Appropriate glove selection depends on the specific repair task. Consider the materials and potential hazards involved.

- Foot Protection: Steel-toe boots or safety shoes are necessary to protect feet from dropped objects or heavy tools. These boots should be worn for added safety in auto repair work.

Tool and Equipment Safety

Proper tool handling and equipment maintenance are critical for preventing accidents. The following guidelines are vital to maintaining a safe environment.

- Tool Inspection: Regularly inspect tools for any signs of damage or wear. Damaged tools should be immediately replaced to prevent accidents. Regular maintenance is vital to prevent accidents. Check tools for loose handles, worn blades, or damaged parts.

- Secure Work Area: Keep the work area tidy and organized to prevent tripping hazards. Unnecessary clutter can increase the risk of accidents. Remove any potential tripping hazards from the work area.

- Proper Lifting Techniques: When lifting heavy parts or components, use proper lifting techniques to avoid back injuries. Use mechanical lifting aids whenever possible. Lift objects with your legs, not your back.

- Electrical Safety: Always disconnect the vehicle’s battery before working on electrical components. Ensure that all electrical tools are properly grounded to prevent shocks. Avoid working with electrical components while the vehicle is powered.

Safety Precautions to Avoid Accidents

Adhering to these safety precautions minimizes the likelihood of accidents during auto repair work. Thorough preparation and awareness of potential hazards are essential. Implement safety procedures to minimize risks.

- Lockout/Tagout Procedures: Implement lockout/tagout procedures when working on machinery or equipment to prevent unexpected startup. Ensure that equipment is safely locked out before performing any repair work.

- Fire Safety: Be mindful of potential fire hazards, such as flammable fluids and sparks. Keep a fire extinguisher readily available in the work area. Ensure that proper ventilation is maintained in the work area to prevent fire hazards.

- Vehicle Stability: Ensure the vehicle is securely supported to prevent it from moving during repair work. Use jack stands or ramps to support the vehicle correctly.

- Communication and Teamwork: Communicate clearly with coworkers about potential hazards or safety concerns. Ensure a clear understanding of the tasks and safety procedures.

Final Conclusion

In conclusion, this comprehensive guide provides a deep dive into the world of auto repair and maintenance. From fundamental knowledge to advanced techniques, we’ve covered the essential aspects of keeping your vehicle running smoothly and safely. Whether you’re a seasoned mechanic or a novice, this guide equips you with the information needed to make informed decisions about your vehicle’s care.

Essential FAQs

What are some common causes of car problems?

Common causes include wear and tear, neglect, accidents, and faulty components. Poor maintenance and driving habits can also contribute significantly.

How often should I change my oil?

Oil change frequency varies depending on the vehicle type and manufacturer recommendations. Consult your owner’s manual for specific guidelines.

What are the benefits of doing DIY repairs?

DIY repairs can save money, provide a deeper understanding of your vehicle, and allow for personalized maintenance adjustments.

What should I look for when choosing a professional mechanic?

Look for certifications, experience, positive reviews, and transparent pricing. A qualified mechanic will understand your vehicle’s specific needs.